While working on my War of the League of Augsburg rules it was apparent that handling the loose figures was not going to work and I needed to base them as groups rather than individuals. But I didn't want to base them all only to find out that a change was needed or, worse yet, that I was scrapping the project and going back to just using them in skirmish games.

Then it struck me that all I really needed was sabot bases that would fit the pennies that the figures were mounted on. A quick search on the internet revealed several sources that would happily make the bases for me; but I would have to wait until they were made and shipped! This wouldn't do.

Fortunately I remembered the device that I had made for cutting portholes in my model boats. Nicknamed "The Shiv" it was little more that a bit of thinwall brass pipe with the end of the pipe sanded to produce a cutting edge around the lip. All I needed to do was find a bit of pipe marginally larger than a penny and I would have a die cutter for my sabot bases.

"The Shiv"

A search of my "useful bits" bin failed to turn up a piece of pipe that was the right size for the project so it was off to the building supply store. Frustratingly the supply of metal pipe did not match (even close) the size of a penny. I dug around until I found a plastic T junction that would work. I took a craft knife and removed a lot of the thickness from the inside of the pipe and then sanded the outside with 60 grit sandpaper to get a finer edge and provide some "tooth" to aid the cutting. Quite pleased with my inventiveness and cunning I tried out my invention on a bit of heavy mat-board that I intended to use for bases. It was a fiasco, the tool left a tidy circular mark on the heavy stock but nothing more.

the T junction after its first test, look how sad it is

Suitably chastened I sat and considered what other material was the thickness of a penny and would be easier to cut than heavy card-stock. Balsa was a failure, just splintering under the pressure, and basswood would be more expensive than laser-cut MDF. By chance my eye fell upon the Proxxon hot wire cutter and, as I stood there wondering why I hadn't put it away as I should, it struck me that the upper layer of a sabot base only needed to be sturdy enough to keep a penny in place. BINGO!! Problem solved!

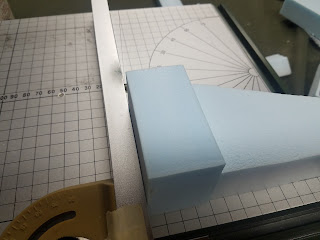

the bases that I needed were 2"x3" so I cut a block of blue board to those dimensions

then I set my faithful sidekick to cut 2mm slices

and I made 2mm thick rectangles

the block on the right is to keep the block that is being sliced true

so that the slices are of a single thickness

in a few moments I had the blocks all sliced up

a closer look at the T junction,

you can see the inside of the pipe where I thinned out the sidewall

and the tiny "teeth" that sanding the outside with coarse sandpaper created

a simple matter to pressing gently and twisting, much like a keyhole saw

and there you have it

five more passes and it is ready to go

initially I intended to mount these on 2'X3" card bases but the "make EVERYTHING out of blueboard" bug bit me again and I just glued the punched layer on top on a blank one

using standard wood glue (which adds desired stiffness as well)

the it occurred to me that I could make irregularly shaped bases for less organized troops

in less time than it took to type this blog entry I made all the bases I needed to hold my nine battalions of 24 figures and a bunch of test bases for my barbarian armies

(somebody come up with a use for all those cool circles I cut out and I will mail them to you free)

six-figure for skirmishers

twelve figure for larger formations

I made bases for over 200 infantry figures in very little time and at nearly no cost. This sort of method can be extended to all sorts of uses; any rule set that calls for large numbers of individually based figures will play faster using such bases to ease movement.

What a fantastic Idea. I can attest to the speed impact of using "troop Trays" on a game - it cuts game length by 1/3 at least for skirmish games

ReplyDeleteI plan on stealing this idea as it's a lot more cost efficient than purchase MDF laser cut ones which has been my practice to date.

My only suggestion is to slip lengths of piano or other stiff wire in between the two layers to add a little bit of stiffness.

Oddly the layer of wood glue seems to handle that stiffness issue, but I have been using plastic figures exclusively.

ReplyDeleteMadness... I see retirement is treating you good.

ReplyDeleteretirement is still treating me terribly, but I sneak away at times and try to have fun!

DeleteSo you are singing and dancing in the woods with nature again...lol

DeleteNow if only he would stop singing and dancing in the woods "au natural"! His predilection of pressing wild flowers is ... well ... disturbing.

ReplyDeleteHey, that is very clever. If you needed a stiffer base for something heavier (metal figures, or bigger figures) you could use wood or metal for the bottom layer of your sandwich.

ReplyDeletePretty nifty and resourceful. 😀

ReplyDeleteWhere do you find blueboard that you used? Is it the same as the blue (and pink) more dense insulation foam board? If there are multiple brands of it do you have a recommendation either to use or avoid any of them?

ReplyDeleteI looked at the site for your Proxxy. A few questions for you from there as well.

1, it says "The correct temperature, being material and thickness dependent, is learned from experience. Profiles are ideally cut at lower temperatures and while applying less cutting force." What do you recommend?

2. There is an AC Adapter NG 2/S NO 38 706 listed as an accessory. Is that a required piece of kit I'd need or do you know what it is for / what it does?

3. How quickly do you go through the wire?

4. Any web sites / YouTube vids / etc. you'd recommend if any of us want to try one out?

Totally unrelated, but I saw your post about Google mislabeling your sites as dangerous. Not exactly the same but on FB, they've gone after a Monty Python fan page. Have to wonder if they are that clueless to not know what MPFC is, or if they are so woke that they can't tolerate Python humor.

The blue board that I'm using is industrial surplus from a local factory. It is largely the same as the pink board and green board that you can get from Big Box home stores such as Lowe's or Home Depot.

ReplyDelete!. Trial and error is how I worked things out, after a little while you get a feel for how the tool works. Try cutting shapes and such using cheap white beaded Styrofoam and low temps. Those weird shaped bits of packing foam are also good to practice on.

2.You don't need an additional power unit for the Thermocut 115E

3. I bought a spare roll when I got the unit, all almost all of the projects that you see on my blog (and dozens more) have been done with the first roll of wire, So, unless you are planning on industrial levels of production, the wire should last a very long time.

4. This guy gives a great rundown on basic operations; https://www.youtube.com/watch?v=4g4dFJojRis

Re; my "dangerous" site, the Woke have no sense of humor, the only emotion they possess is the petulant outrage of a spoiled three-year-old who isn't getting their way. There is no way they could even comprehend Python's level and style of satire, but they sure will complain about it!

Thanks for the info! I appreciate it.

ReplyDelete